BVO IR Polarizer

BVO IR (700nm-1,600nm) covers the near infrared polarizer bandwidth. Modern NIR applications often require polarized light for fiber optics, imaging or solid state sensing. Use BVO IR as a solution to polarize incoming light, increase contrast or reduce glare in the near infrared up to 1,600nm.

Near Infrared DIchroic Linear Polarizer

- Active Range: 700nm – 1,700nm

- Best true NIR polarizer

- Type – transmissive, absorptive

- Polarize 740nm, 780nm, 850nm, 870nm, and 940nm LED’s

- Polarize 785nm, 808nm, 830nm, 905nm, 980nm, and 1,064nm laser diodes

- Polarize 1,310nm and 1,550nm optical communications

- All NIR low power lasing sources

- NIR Imaging capable

- BBAR coated BK-7 components available

- Polarize portion of SWIR

- Replaces 3M polarizer – HR

Applications

- Surveillance & Security

- Defect Identification for Sorting

- Machine Vision Imaging – Glare Reduction

- NIR Sensors – Optical, Solid State

- Multispectral Imaging

- Agriculture Inspection

- NIR Polarized Microscopy

- NIR Cameras, Photography

- NIR Semiconductor Inspection

- NIR Raman Polarized Spectroscopy

- NIR Astronomy

- NIR Thermography

Spec Downloads

Film Specifications

| Polarizer Range | 700nm – 1,700nm |

| Contrast Ratio | 3,000:1, nominal |

| Maximum Dimension | 60mm x 55mm |

| Thickness | .40mm |

| Film Cutting Tolerances | ± 50 microns |

| Adhesive (PSA) | None |

| Temperature Range | -20° C to 60° C |

| Damage Threshold | 1 W/cm2, CW 0.2 J/cm2 with 20 nsec pulse, visible |

| Color | Dark Green |

| Substrate | Plastic Type, “Cellulose Triacetate”, dichroic |

| Surface Quality | 80/50 Scratch-Dig |

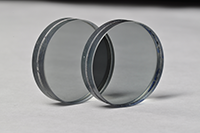

Component Specifications

| Outer Dimension | 25.4mm OD ± 0.20mm |

| Wavefront Distortion | Lambda/2 measured @ 632nm |

| Thickness | 4.5mm, ± 0.20mm |

| Substrates | BK-7 |

| Surface Quality | 40/20 Scratch-Dig |

| Beam Deviation | 2 Arc Minutes |

| Anti Reflection Coatings | R ≤ 0.65% / surface, average. 400nm-900nm R ≤ 0.65% / surface, average. 700nm-1,100nm R ≤ 0.65% / surface, average. 900nm-1,700nm |

| Environmental Tolerance | -10° C to 60° C |

OPTIONAL LAMINATION SUBSTRATES :

Optical Grade BK-7

Low Wavefront Distortion Glass

- Industry standard optics glass

- Good transmission visible and NIR

- Best for low wavefront distortion

- Thickness flexibility

- Double side polished, lambda/10 flatness

- Refractive index – 1.52

BK-7 Glass Transmission Chart

Bk-7 Optional NIR BBAR COATING

- R ≤ .65% per surface, avg.

- Ultra broad range, 400nm to 950nm

400-950nm BBAR on BK-7 scan – typical

Corning Display Glass

Results in thin final components

- Thin glass, excellent clarity

- No residual birefringence

- Imaging quality flatness

- No added heavy metals

- 0.5, 0.7mm, 1.1mm options for thickness

- Refractive index – 1.50

Corning Glass Transmission Chart

Eagle XG Optional NIR BBAR COATING

- R ≤ .65% per surface, avg.

- Ultra broad range, 400nm to 950nm

400-950nm BBAR on Eagle XG scan – typical

Non-Birefringent Acrylic

Inexpensive Complex Shapes

- No residual birefringence substrate

- Cheapest option for laminated products

- Digitally cut for all geometric shapes

- Thin flexible substrate (bends)

- 0.2mm – 5.0mm options for thickness

- Refractive index – 1.49