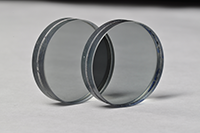

BVO VIS DS Polarizer

(Formerly called BVO 125) Overcome the polarizer LED burn encountered by new intense light sources by using BVO VIS DS robust dyestuff linear polarizer. Machine vision requires polarization to eliminate glare and new LED sources can burn traditional iodine based linear polarizer. Some caustic environments such as blue LEDs bleach standard iodine polarizers while other environments such as automobiles require a higher temperature tolerance. Dyestuff polarizers are the best bet to ensure linear polarizer survival.

Dyestuff High Durability Visible Linear Polarizer

- Active Range: 420nm – 650nm

- Resists LED burning

- Type – transmissive, absorptive

- Overcome machine vision polarizer burn-in

- Exceptional environmental durability

- High temperature linear polarizer

- Tougher than iodine based polarizer

- Blue LED extended polarizer lifespan

- Robust PSA

Applications

- Rugged Display

- Automotive

- Durable Sensors

- Visible LED Sources

- 405nm LED Machine Vision

- Projection Systems

Downloads

Film Specifications

| Polarizer Range | 400nm – 700nm |

| Contrast Ratio | 1000:1, nominal |

| Maximum Dimension | 1000mm x 630mm |

| Thickness | .170mm |

| Film Cutting Tolerances | ± 50 microns |

| Adhesive (PSA) | Yes robust type, custom order for NO PSA |

| Temperature Range | -20° C to 80° C |

| Damage Threshold | 3 W/cm2, CW > 0.2 J/cm2 with 20 nsec pulse, visible |

| Color | Neutral Gray |

| Substrate | Plastic Type, “Cellulose Triacetate”, dichroic |

| Surface Quality | 80/50 Scratch-Dig |

Component Specifications

| Outer Dimension | 25.4mm ± 0.20mm |

| Wavefront Distortion | Lambda/2 measured @ 632nm |

| Thickness | 4.20mm ± 0.20mm |

| Substrates | BK-7 |

| Surface Quality | 40/20 Scratch-Dig |

| Beam Deviation | 2 arc minutes |

| Anti Reflection Coatings | R ≤ 0.65% / surface, average. 400nm-900nm |

| Environmental Tolerance | -10˚ C to 70˚ C |

OPTIONAL LAMINATION SUBSTRATES

Optical Grade BK-7

Low Wavefront Distortion Glass

- Industry standard optics glass

- Good transmission visible and NIR

- Best for low wavefront distortion

- Thickness flexibility

- Double side polished, lambda/10 flatness

- Refractive index – 1.52

BK-7 Glass Transmission Chart

Bk-7 Optional BBAR COATING

- R ≤ .65% per surface, avg.

- Ultra broad range, 400nm to 900nm

400-900nm BBAR on BK-7 scan – typical

Corning Display Glass

Results in thin final components

- Thin glass, excellent clarity

- No residual birefringence

- Imaging quality flatness

- No added heavy metals

- 0.5, 0.7mm, 1.1mm options for thickness

- Refractive index – 1.50

Corning Glass Transmission Chart

Corning Glass Optional HEA BBAR COATING

- R ≤ .65% per surface, avg.

- Visible range, 425nm to 685nm

Visible HEA BBAR scan – typical

Non-Birefringent Acrylic

Inexpensive Complex Shapes

- No residual birefringence substrate

- Cheapest option for laminated products

- Digitally cut for all geometric shapes

- Thin flexible substrate (bends)

- 0.2mm – 5.0mm options for thickness

- Refractive index – 1.49

Non-birefringent acrylic transmission chart

Acrylic Optional AR Coating

- R ≤ 1% per surface, avg.

- Visible range, 425nm to 700nm